제품소개

고객의 요구를 최우선으로 생각하며, 맞춤형 솔루션을 제안하는 (주)엠워텍

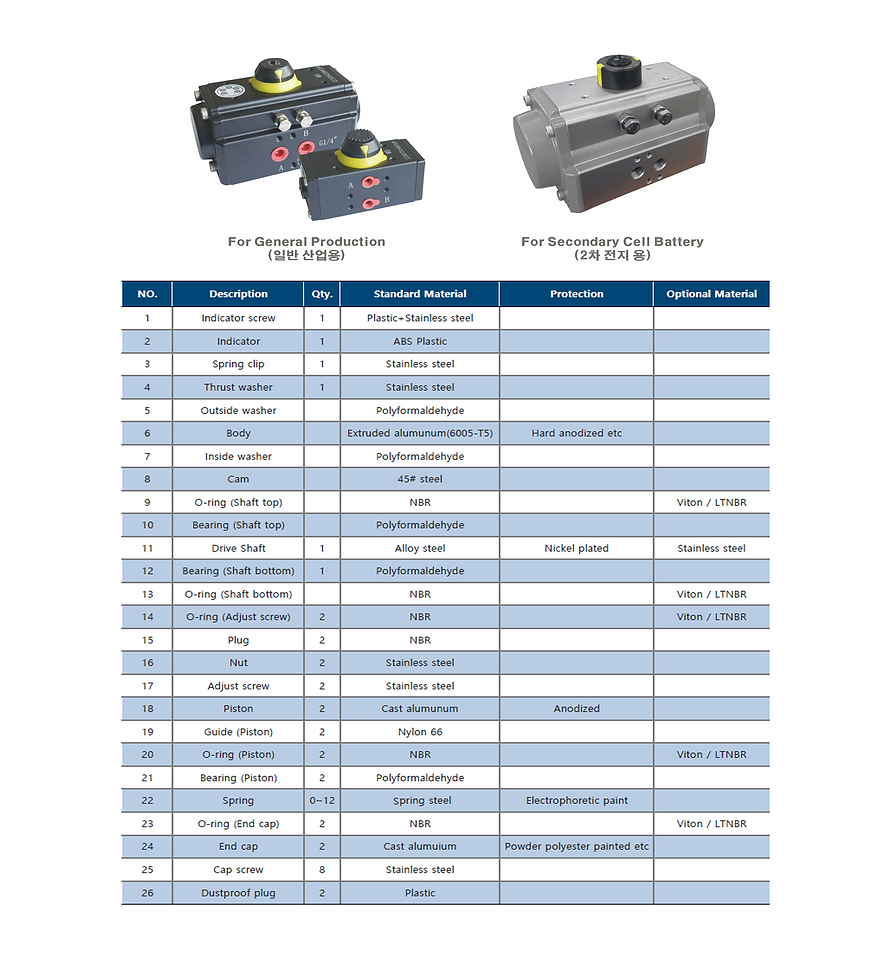

Technical Characteristics

AT series pneumatic actuators utilize advanced precision machining equipment, high-quality materials, and industrial design technology. After rigorous testing and production line optimization, the ARC series pneumatic actuators offer numerous advantages, including smooth and reliable operation, long service life, excellent corrosion resistance, flexible configurations, and competitive pricing.

1. Piston

The piston teeth are precisely machined using a CNC machining center, ensuring smoother operation and improved reliability. An anodized surface treatment enhances corrosion and wear resistance.

2. End cap

The 95° position limit function is optimally designed within the end cap, eliminating the need for an additional limit screw. This design enhances both safety and reliability.

3. Fasteners

The staninless steel fasteners, are safe and beautiful with high corrosion resistance

4. Spring

Preloaded and coated springs are made from high quality material for higher corrosionresistance and longer service life, which can be demounted safely and conveniently to satisfy different requirements of torque by changing quantity of springs ners, are safe and beautiful with high corrosion resistance

5. Power polyester

According to different requirements, the surface of aluminum body can be treated with hard anodizing powder polyester coating in colors, PTFE coating or nickel plated

6. Drive shaft

The drive shaft is high-precision and intergrative, made from nickel plated alloy steel, full conform to the lastest standards of ISO5211, DIN3337, NAMUR. The dimensions can be customized and the stainless steel is available.

7. Adjust screw

The two independent external travel stop adjust screwscan adjust ±5˚ at both open and close positions easily and precisely.